04Step Motors/Drivers

Home > Products - Step Motors/Drivers

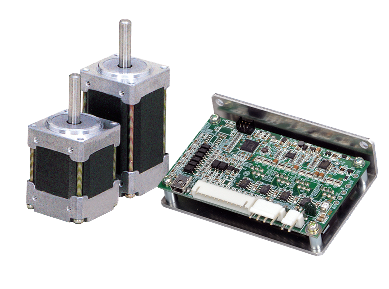

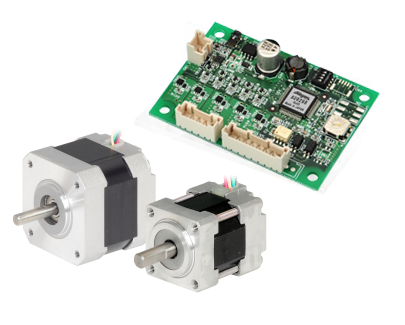

Simple positioning control by high torque and sensorless motors

Abundant lineup correcsponding to various application

Step Motors/Drivers

Step Motors/Drivers

The step motor is a motor that can perform open loop control without the need for a feedback mechanism. It features small size, light weight, high torque, and low price. This type of motor can be controlled more simply than a servo motor.